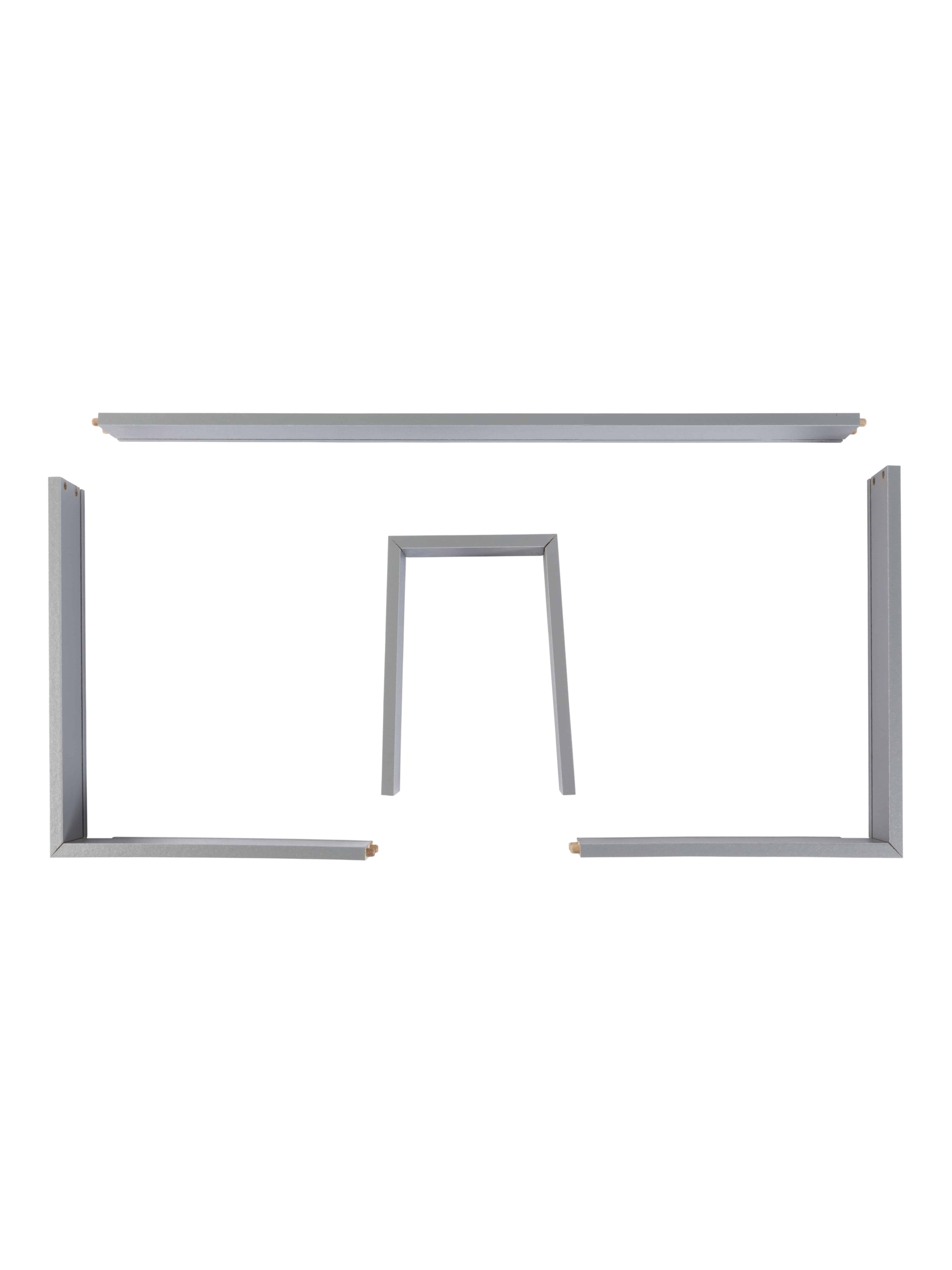

Folding drawers

The folding drawers join the pieces of the drawer with a mitre exactly at 90º so that when folded the two pieces are joined together. 1, 2 or 3 can be made to form up to 4 pieces in this basic folding model. The internal machining is made to measure for each customer and we are used to working with all types of metal slides and with all the suppliers on the market. We always recommend that you consult us before choosing a slide, as many of the drillings are siblings of each other and we can make several different machining processes, so that the furniture is more versatile and different slides can be incorporated.

Drawers kit

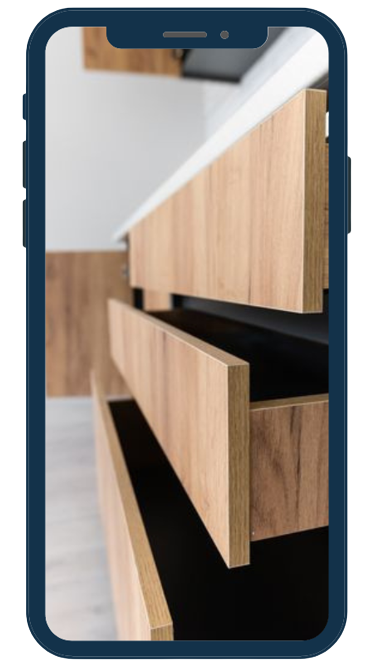

We make the drawers with independent pieces ready for the final customer to assemble them in the furniture assembly process. We can do all types of machining and insert as many dowels, pre-glued dowels or plastic dowels. We also custom make the low groove to insert the bottom in the thickness you need. We have more than 20 different designs that you can choose from for the coating of the parts, the internal machining is made to measure for each customer and we are used to working with all types of metal guides and with all the suppliers on the market. We always recommend that you consult us before choosing a slide, as many of the bores are siblings of each other and we can do several different machining, so that the furniture is more versatile and different slides can be incorporated.

THIS IS WHAT WE DO

1. TYPES OF DRAWERS

Our unwavering commitment to quality and excellence drives us to create products of the highest quality, ensuring that every profile and every part we produce meets the highest standards.

Siphon drawer

We have a lot of experience in special drawers, such as these that avoid using the necessary hole for the siphon in a bathroom or kitchen drawer. They can be made with as many mitres as you wish, in the photo on the left you can see up to 8 mitres, so that the drawer is very easy to assemble. It is also common to make less long drawers and reduce to a maximum of 3 mitres per piece, composing the siphon saver drawer in 3 independent pieces. With this variety of special crates we can reach all customers and offer tailor-made solutions that improve either their assembly or their packaging process and quality. In addition, as its coating process is in one step, PP makes the piece hermetic against humidity and heat, offering greater resistance than any other alternative on the market.

QUALITY IS OUR RAISON D'ÊTRE

Foldeco's quality and quality control processes are the most demanding on the market. on the market. We are going to explain 4 of the most remarkable ones

FIRST PIECE

Our parts are triple-checked on their first registered part. In addition, all visual and dimensional points are checked every 50 pieces during production.

FMA

We keep a record of the most frequent errors, both mechanical and human, and mechanical and human errors and keep a statistical control of them to avoid repetition.

LEAN

All production and management processes of the company are designed according to the LEAN method, including quality, to make it more optimal and efficient. We are already preparing for the next step, LEAN KATA

5S

Sort, Set in order, Shine, Standarize and Sustain. (order), Shine (cleanliness), Standarize (standardisation) and Sustain (discipline). These are the 5 pillars of 5S, implemented at Foldeco since 2021 to make our factory a a cleaner and tidier place that supports quality.

2.

TECHNICAL DATA

3. BOTTOMS AND BACKS

We are a great laminate specialist, offering in this range the laminated backs and bottoms to the customer. We can achieve any design, any melamine on the market, so the first attribute our customers see is that the design model is the same as the one they have themselves. With that design, inside the drawer they can mount our laminate backs, offering as a value the resistance to humidity and scratching there, much better than our main competitor, lacquer. In the back of the cabinet, we are able to laminate and fold, so that our back becomes an accordion much easier to assemble, both for our customer and for the end customer. The trend product in cabinets is the folding back, as it saves a lot of assembly time compared to the It saves a lot of assembly time compared to full backs or those glued with tape and the finish is perfect, because we do not cut the beta of the design and everything is visually uniform. In addition, we can machine these back panels according to the customer’s wishes with drilled holes or cut-outs.

4. FURNITURE FRONTS

Shaped fronts

One of our specialities is shaped or straight, very narrow (from 80mm high) or very high (up to 450mm) coated fronts to give the solution you need for your furniture. Of course, we offer it finished, edged and machined, ready for assembly.

OTHER FRONT DESIGNS

At Foldeco we are specialists in coating shapes of all sizes in a single pass, obtaining products like these products like these. Please, count on us for any kind of shape on your parts. shape on parts.

MELANIN FRONT

At Foldeco, our specialists in edging three-sided pieces, with a fully automated machine that edges the 2 long pieces, trims the edge of the 2 short pieces and drills in the same operation, providing a quality solution at an advantageous price. drills in the same operation, providing a quality solution at an advantageous price.

6. Rails + reinforcements

Foldeco Products

TYPE 1

TYPE 2

7. Drawer guide

We have in stock guides from 250 mm to 600 mm long with clamp type fixing. Our main novelty and point of differentiation with the competition is the fact that we can supply it already assembled.

Do not hesitate to ask us for more information!

Don’t hesitate to ask us for any information!

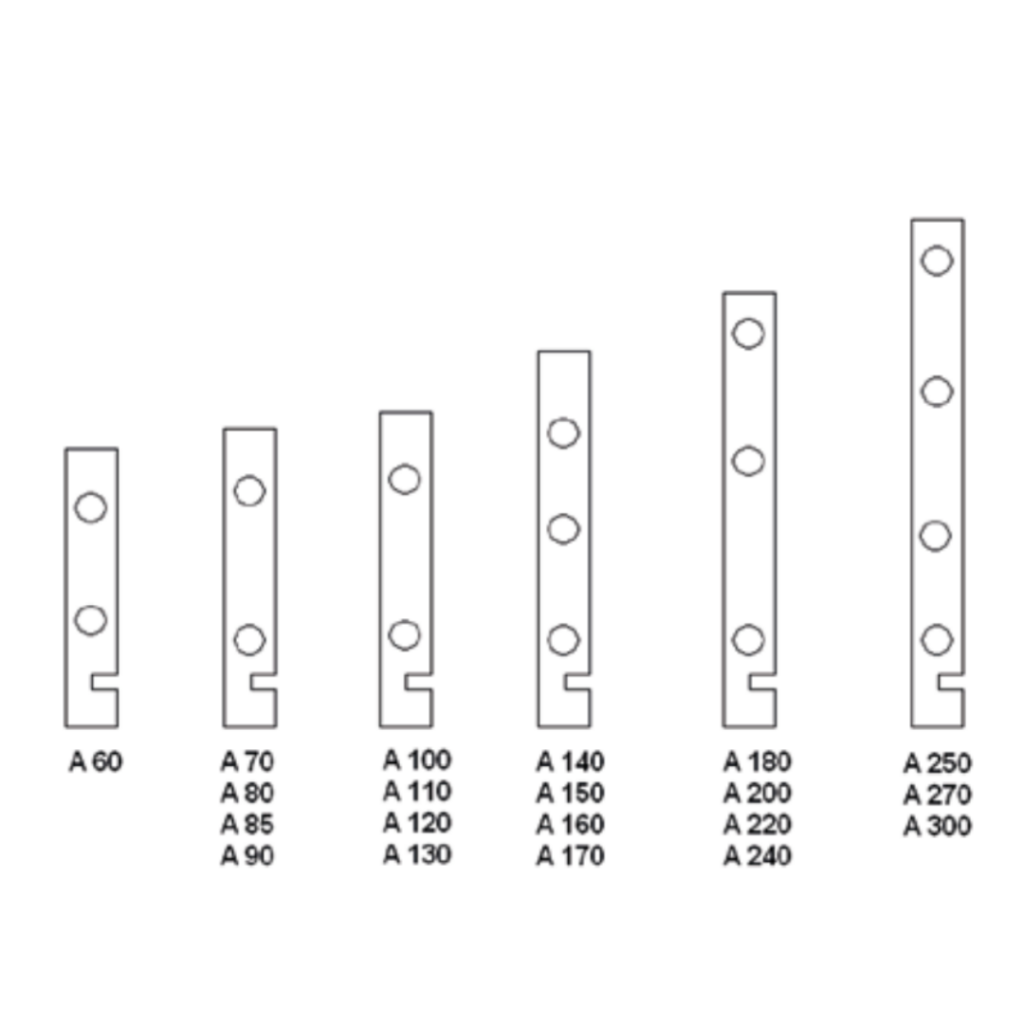

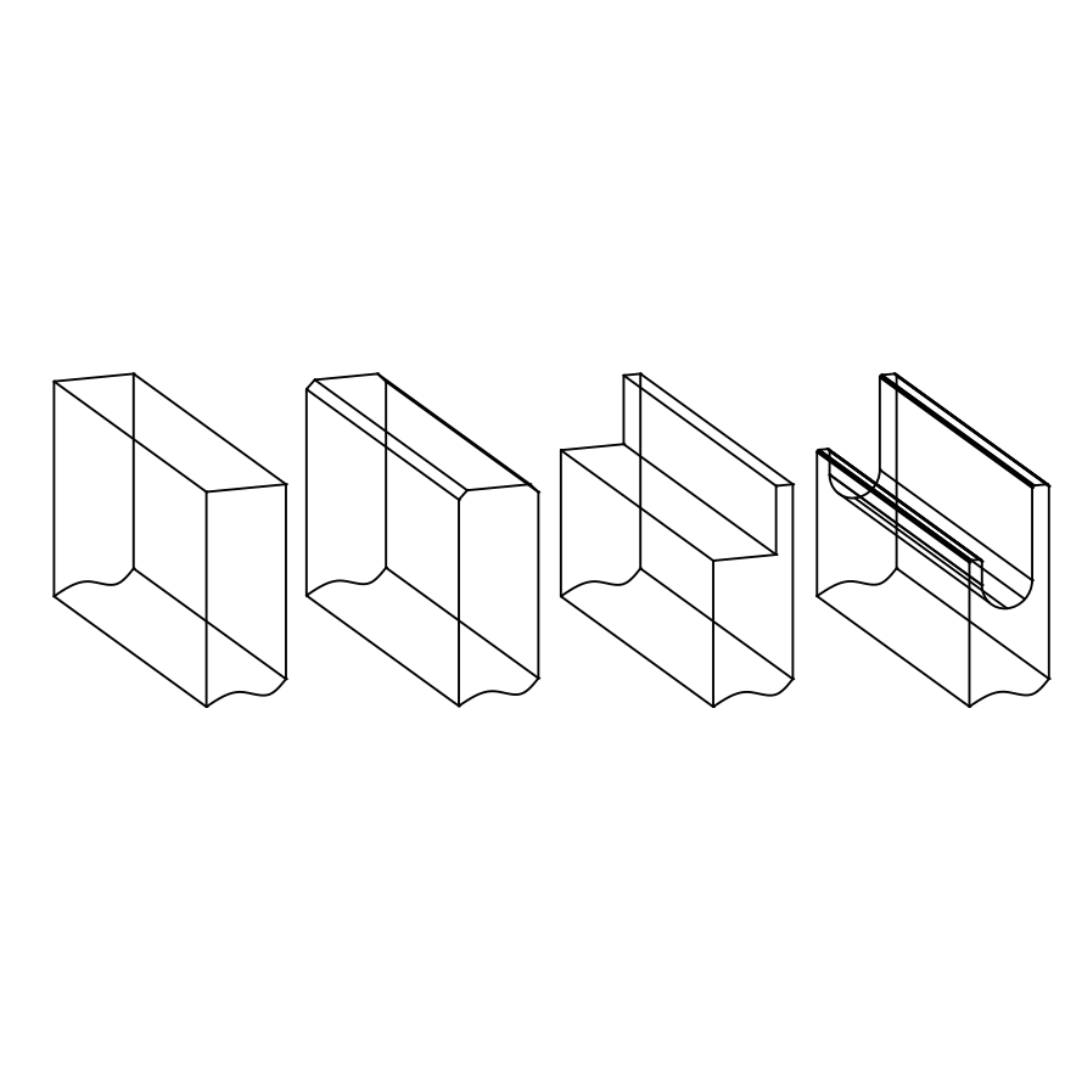

BOX PROFILES: Chipboard or medium density fibreboard with a standard thickness of 12 mm. covered with a PVC or Polypropylene sheet in different heights, lengths, dowel and hole positions and folding, as detailed below.

SIZES AND FINISHES

AVAILABLE HEIGHTS A: profile with 17.50 mm centre groove.

AVAILABLE HEIGHTS B: profile with groove for the bottom of 4 mm. C: profile with inverted “L” top edge.