How to improve the humidity resistance of a piece of furniture?

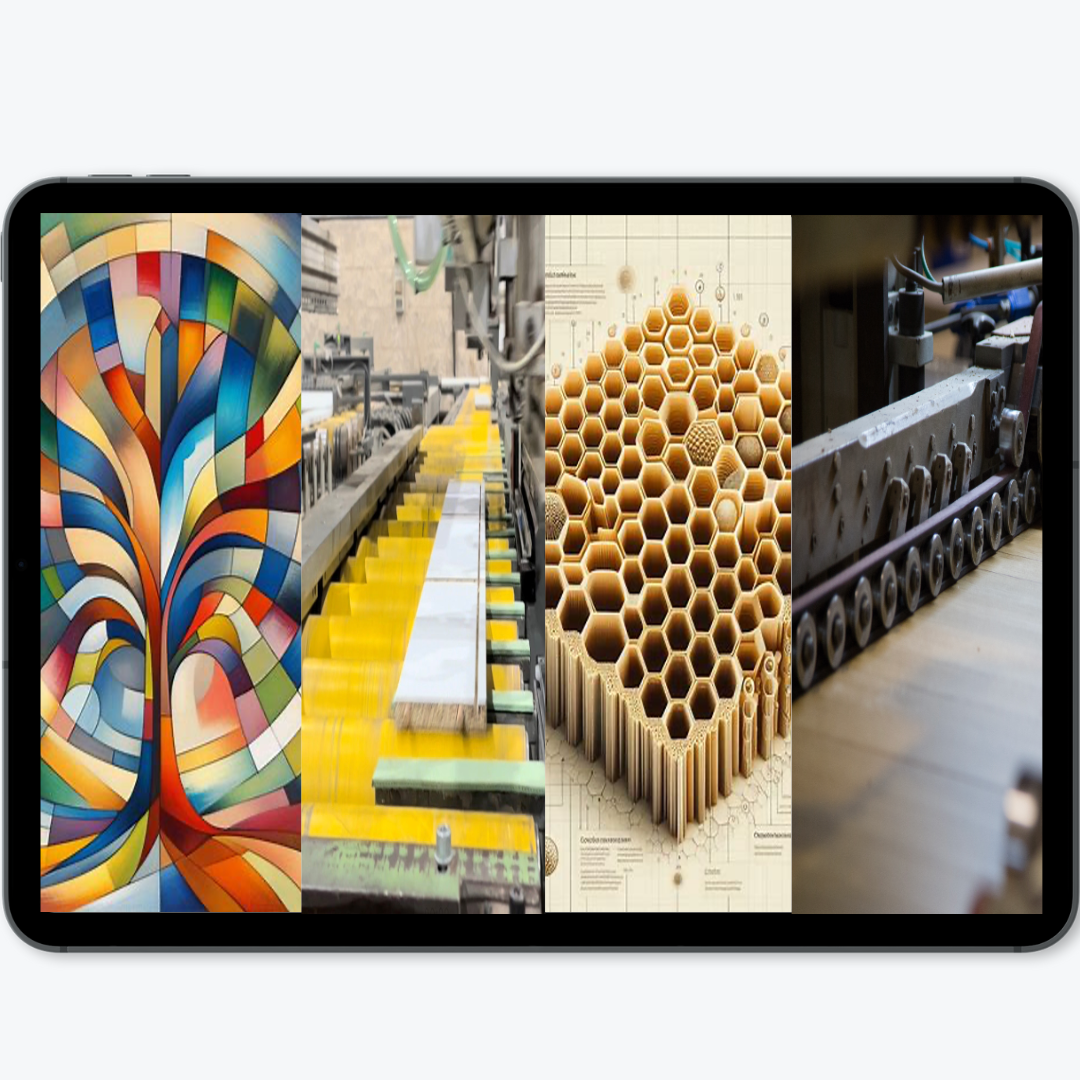

PROGRAM

Moisture resistance

Make more sustainable furniture and reduce the carbon footprint

Create uniformity within the furniture

FOLDECO

WHY IMPROVE MOISTURE RESISTANCE

Wood always suffers from changes in temperature and humidity. It is a living material and expands or contracts when these phenomena occur.

In a piece of furniture that may have little proximity to the most humid areas of the house, it is not necessary to protect it, but it is necessary in the terrace, kitchen and bathroom areas.

Foldeco has become a great specialist in moisture protection, not only with the use of water-repellent boards, but also by sealing the edges.

A MORE SUSTAINABLE FURNITURE

PUR TAIL

The use of high humidity resistance glues on the entire surface of the product is essential. At Foldeco we use PUR glue, the most resistant on the market in all our coatings, laminates and edging.

THE SEALING OF THE EDGES

Sealing the edges is essential, because a drop of water always falls inside the drawer. By sealing the edges, these ends are greatly protected, making a surface impenetrable to moisture.

AND WHAT IS ITS VISUAL COMPLETION?

Edge finishing

Edgebanding of short films fully protected

The edges are protected against any direct or indirect humidity.

And all types of perforations can be made

THE BASICS OF HUMIDITY CONTROL

Rough edges

The raw board does not protect against moisture

Coated edges

Coated edges also provide protection, but moisture can get in at the ends.

Protect uncoated edges

The edge always protects, the sealing protects the entire workpiece.

Hygrophobic board

The water-repellent base provides additional protection, including for drilled or profiled parts.

MAKING SUSTAINABLE FURNITURE

PROGRAM

Moisture resistance

Making furniture more sustainable and reducing carbon footprint

Create uniformity within the furniture

MAKING FURNITURE MORE SUSTAINABLE

Making melamine furniture more sustainable involves considering several aspects from the beginning of the project to its realisation. Firstly, the choice of board certified to environmental standards, such as FSC or PEFC certification, ensures that the wood used comes from sustainable and well-managed sources, and low formaldehyde-emitting board can be chosen, thus reducing the release of harmful chemicals into the environment. During manufacturing, optimising the cutting of boards to minimise material waste contributes to greater efficiency and sustainability. Considering the use of eco-friendly adhesives and finishes, as well as exploring modular designs that allow parts of the furniture to be disassembled and reused, can extend its life and reduce the amount of waste. Ultimately, proper waste management, including melamine recycling, closes the sustainable furniture cycle. Integrating these practices promotes the manufacture of melamine furniture in a more environmentally friendly way.

MORE SUSTAINABLE FURNITURE

THE WOOD

Choosing board certified to environmental standards, such as FSC or PEFC certification, ensures that the wood used comes from sustainable and well-managed sources. In addition, you can choose to use low-formaldehyde-emitting board, thus reducing the release of harmful chemicals into the environment.

THE OTHER COMPONENTS

It is very important to help the separation of the different components at the end of the furniture’s useful life. In this way, apart from reducing plastics as a raw material for the board, it is important to reduce the use of other components, especially metal fittings and, if they are introduced, to make them easy to dismantle. This will improve the separation of the different components.

FOLDECO

REDUCE CARBON FOOTPRINT

Reducing the carbon footprint of a piece of furniture is essential to promote sustainability in furniture design and manufacturing. Firstly, selecting sustainably sourced materials, such as certified wood or low environmental impact alternatives, contributes significantly. Opting for more efficient manufacturing processes and clean production technologies helps to minimise energy consumption and greenhouse gas emissions. Smart design, which maximises material utility and reduces waste, is also key. Promoting furniture durability through robust assembly techniques and strong materials ensures a longer service life, reducing the need for replacement and thus additional production. In addition, the use of environmentally friendly finishes and adhesives contributes to an overall reduction of the carbon footprint. Finally, encouraging reuse, recycling and proper waste management at the end of the furniture’s life completes the sustainable approach. Integrating these practices into the design and manufacturing process is crucial to mitigate the carbon footprint associated with furniture.

THE BASICS OF HUMIDITY CONTROL

Sustainable board

Always use wood from sustainable sources, well cut, better recycled.

Reduction of unsustainable materials in wood

Reducing the use of harmful chemicals in manufacturing and the use of plastics in finishes

Optimising processes

Being more optimal, using more modern and efficient machinery, also helps the Planet.

Reducing the footprint of packaging

Reducing the use of natural wood in pallets, using recycled cardboard for packaging and less plastic is a very high point that will help your company stand out from the competition.

Minimising the transport footprint

Efficiency in processes, having everything centralised and close to the large sales centres, undoubtedly helps to reduce the carbon footprint.

CREATE UNIFORMITY WITHIN THE FURNITURE

PROGRAM

Moisture resistance

Making furniture more sustainable and reducing carbon footprint

Create uniformity within the furniture

CREATE UNIFORMITY WITHIN THE FURNITURE

Furniture should always give a feeling of robustness and resistance and designers almost always aim for uniformity. Uniformity of design in furniture is not only aesthetically pleasing, but also functional. When furniture shares a cohesive design, it creates visual harmony in the space, makes it easier to combine elements and creates a sense of order. In addition, uniformity can simplify decision-making when choosing new furniture, as a consistent colour palette or style is maintained. However, it is crucial to balance uniformity with the need for diversity to avoid a monotonous environment. Ultimately, uniformity in furniture design contributes to the creation of balanced and pleasing environments.

WHERE DOES FOLDECO HELP?

INSIDE THE DRAWER

We can offer the sides covered with the same foil, with the same design as we laminate the bottoms. Therefore, we create harmony in the interior.

OUT OF THE DRAWER

Our fronts, which can be coated, laminated or in melamine, can also have the same design as the interior pieces, providing even greater harmony. This design on the fronts can also be reproduced on the sides and ceilings, between all the pieces of furniture.

AND WHAT IS ITS VISUAL COMPLETION LIKE?

One drawer complete with "J" shaped front in the same white

One full drawer with "J" shaped front in the same linen.

The cabinet shell can be combined with different designs for the inside of the cabinet.

Or use the same design as here

THE STEPS OF HARMONY IN FURNITURE DESIGN

The 3 pieces of the drawer on the same sheet of paper

The 3 pieces with the same design is for us a minimum for the generation of harmony.

Backgrounds in the same design

Harmony with the background is highly recommended, and our laminated backgrounds are extremely resistant to humidity.

The fronts with the same design

Harmony rises and is discovered when the drawer is opened.

All integrated furniture

Total integration, all uniform with the same design, including all visible parts of the furniture.